Intro to Polycarboxylate Superplasticizers

Polycarboxylate superplasticizers have emerged as a cutting edge additive in the construction market, substantially boosting workability and durability and reducing the cement material of concrete. Compared to conventional superplasticizers, polycarboxylates not just boost building performance but also support ecological sustainability and environment-friendly building techniques.

(TRUNNANO polycarboxylate superplasticizer)

Architectural Distinctions

From a chemical structure perspective, traditional superplasticizers, such as naphthalene or lignosulfonate-based, mainly count on adsorption onto cement particles to produce electrostatic repulsion for dispersion. On the other hand, polycarboxylate superplasticizers feature an one-of-a-kind comb-like macromolecular structure; this permits them to generate both electrostatic repulsion and steric obstacle, stopping the re-agglomeration of concrete particles. As a result, polycarboxylates accomplish superior dispersion at lower concentrations and exhibit greater security under varying environmental conditions, such as temperature adjustments.

Efficiency Comparison

First of all, in terms of water reduction, polycarboxylate superplasticizers can typically provide over 40% water decrease, far going beyond the capacities of standard kinds. Secondly, while preserving the very same level of flowability, making use of polycarboxylate superplasticizers significantly minimizes the amount of water and cement needed, resulting in cost financial savings and minimized environmental influence. Furthermore, for high-strength and high-performance concretes, polycarboxylates demonstrate superb compressive strength growth, improving the mechanical residential or commercial properties after setting. Lastly, these products show great compatibility with various kinds of concretes and admixtures, decreasing quality fluctuations as a result of raw material variants.

Environmental Sustainability

As global recognition of environmental management rises, there is a growing preference for structure products that are harmless to human health and have very little ecological impact. Unlike some traditional superplasticizers that may include unsafe components, polycarboxylate superplasticizers have lower VOC (unpredictable natural compound) emissions and better biodegradability, making them a lot more straightened with modern-day environment-friendly building requirements. Additionally, their ability to reduce resource usage without jeopardizing performance makes them an economically and eco-friendly selection.

( TRUNNANO polycarboxylate superplasticizer)

Application Areas and Future Prospects

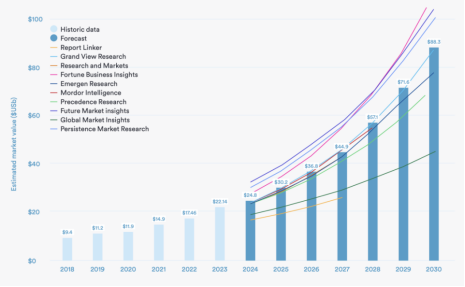

Polycarboxylate superplasticizers are extensively utilized in a range of concrete projects, consisting of high-rise buildings, bridge building, and tunneling. They are particularly favored in applications calling for high-performance concrete, such as the manufacturing of prestressed concrete components. As modern technology progresses and market need increases, polycarboxylate superplasticizers are expected to discover brand-new and cutting-edge applications, driving the construction industry toward better effectiveness and even more lasting practices.

High-quality Polycarboxylate Superplasticizer Distributor

Cabr-Concrete is a supplier of Concrete Admixture under TRUNNANO with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality plasticizer and superplasticizer in concrete, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us